The Science Behind Solar Panel Cleaning Technology

Solar energy has revolutionized the way we power our homes, businesses, and communities. But behind every efficient solar panel system lies a lesser-known yet critical element: solar panel cleaning technology. As dust, grime, and bird droppings accumulate on solar modules, energy output can plummet by up to 25–35%, especially in dusty or industrial regions. Enter robotic solar panel cleaners—precision machines engineered to keep solar panels operating at peak performance with minimal human intervention. In this article, IFBOT, a trusted manufacturer of solar panel cleaning robots, breaks down the science and innovation driving these game-changing devices.

What Is Robotic Solar Panel Cleaning Technology?

Robotic solar panel cleaning technology involves automated systems that remove debris from photovoltaic (PV) modules using a combination of mechanical brushes, vacuum suction, water jets, or a combination of these methods. These machines are designed to operate autonomously, adapt to varying panel angles and surfaces, and work in diverse environments, from flat rooftops to expansive solar farms.

Core Mechanisms Behind the Technology

1. Intelligent Navigation and Control Systems:

Advanced robots like IFBOT X3, M20, and UAV are equipped with AI-powered navigation systems. These systems use edge-detection sensors, gyroscopes, and model-predictive control algorithms to map panel layouts, plan cleaning paths, and avoid obstacles or panel boundaries with precision.

2. Brush and Suction Systems:

IFBOT X3, for instance, uses treated nano-fiber brushes combined with vacuum suction. This enables dry cleaning without water, making it ideal for arid regions or facilities aiming to conserve water. The brushes are designed to be gentle on glass surfaces, preventing scratches or micro-cracks.

3. High-Pressure Water and Dual-Brush Technology:

IFBOT M20 employs a robust dual-brush design coupled with controlled water jets. It integrates Dynamic Mud-Water Separation to clean its brushes during operation, recirculate used water, and minimize waste. This ensures high cleaning efficiency even in areas with stubborn grime or bird droppings.

4. Aerial Deployment with UAV Integration:

The UAV system demonstrates true innovation in large-scale maintenance. It autonomously deploys cleaning robots on hard-to-reach areas, guided by GPS, altitude control, and intelligent docking mechanisms. This is especially effective for ground-mounted solar farms or installations with complex terrain.

Science-Driven Benefits of Robotic Cleaning

1. Maximized Energy Yield

Dust and dirt reduce light absorption. Robotic cleaning ensures consistent energy output. In desert climates, energy gains of 30–40% have been recorded after switching to robotic systems.

2. Water Conservation

Dry-cleaning robots like the X3 save 5,000 liters of water per MW per cleaning cycle compared to manual hose-and-brush methods.

3. Labor Safety & Cost Reduction

Manual cleaning poses fall risks and requires hours of human labor. Robots reduce man-hours and injury rates, offering ROI in as little as 1–2 years.

4. Extended Panel Lifespan

Robots apply even pressure and avoid thermal shocks, preventing micro-cracks and hotspots. This helps extend solar panel life and reduces long-term maintenance costs.

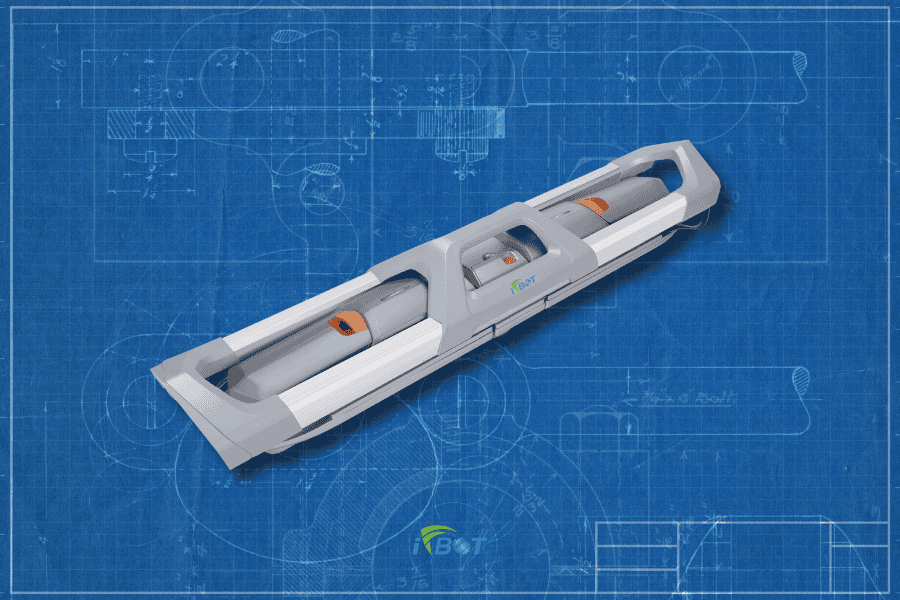

IFBOT: Innovation at the Forefront

IFBOT’s product suite embodies the latest in solar panel cleaning innovation. Whether it’s the ultra-light IFBOT X3 for rooftops, the powerful M20 for industrial cleaning, or the UAV-integrated system for remote deployment, each product reflects cutting-edge research and engineering.

Bonus: FAQs about Solar Panel Cleaning Robots

Q1: How does a robotic solar cleaner navigate panels?

A1: Through edge-detection sensors and AI, robots map out panels and avoid obstacles or drops automatically.

Q2: Can solar panel robots work on sloped rooftops?

A2: Yes, IFBOT X3 supports up to 50° tilt using suction for grip.

Q3: Is robotic cleaning safe for panels?

A3: Absolutely. IFBOT uses soft microfiber brushes and smart force application to prevent scratches or cracks.

Q4: Do robots require water to clean panels?

A4: Not always. IFBOT X3 is a dry-cleaning model; the M20 uses water, but recycles it to minimize consumption.

Q5: What is the ROI for robotic cleaners?

A5: Most systems pay for themselves within 1–2 years due to energy gain and labor savings.

Want to see these robots in action or schedule a free demo? Contact us today and make the smart move towards sustainable solar panel maintenance.