Dry vs Wet Solar Cleaning Robots: Key Differences

Dry vs Wet Solar Panel Cleaning Robots: What’s the Difference and Why It Matters

Solar energy output depends on one thing that often gets overlooked: how clean the panels are. Dust, sand, pollution, bird droppings, and industrial residue can reduce power production by 5–30%, and in some regions even more.

For large solar farms and commercial rooftops, keeping panels clean is not optional — it’s a core part of performance and ROI.

Today, solar operators are increasingly turning to robotic cleaning systems to reduce manual labor, improve safety, and ensure consistent efficiency. But one question still comes up in almost every project:

Should you choose a dry cleaning robot or a wet cleaning robot?

This article breaks down both methods, explains the differences, and shows how to choose the right solution for your site — using real operational logic, not guesswork.

(And yes, we’ll also explain where IFBOT X3 and IFBOT M20 fit into the picture.)

1. Why Solar Panel Cleaning Methods Matter

Before comparing dry vs wet robots, it’s important to understand why the cleaning method affects more than just the cleaning itself:

Energy yield & annual production

Water availability and usage cost

Labor demand and operator safety

Maintenance cycles and robot lifespan

Environmental impact (especially in desert or remote sites)

Overall ROI and O&M strategy

Choosing the wrong cleaning method can lead to over-cleaning, under-cleaning, or wasted resources.

2. What Is Dry Cleaning?

Dry cleaning robots rely only on mechanical action — typically rotating microfiber rollers or brushes — to remove dust and loose debris.

How dry robots work

Soft rollers lift dust without scratching the surface

Lightweight structure reduces load on panels

Ideal for daily or frequent cleaning cycles

Zero water used

Low O&M cost

Very fast cleaning speed

Best for:

Desert regions with extreme dust

Water-scarce countries (Middle East, India, Australia)

Utility-scale farms with large surface areas

High-tilt rooftops where water would run off instantly

Sites needing daily/weekly cleaning cycles

Key Advantages

No water logistics or tanking costs

Lowest cost per cleaning cycle

Lower carbon footprint

Suitable for automated nightly cleaning

Protects panel coatings when using soft rollers

Where IFBOT fits

The IFBOT X3 is a fully dry-cleaning robot designed to be:

80% lighter than conventional robots

Easy to carry and deploy on rooftops or commercial arrays

Safe for framed and frameless panels

Highly effective for light to medium dust accumulation

It’s award-winning for a reason — dry cleaning done right is incredibly efficient.

3. What Is Wet Cleaning?

Wet cleaning robots use a water spray system combined with brushes or rollers to remove sticky, oily, or crusted debris.

How wet robots work

Water dissolves hardened dirt

Brushes remove stubborn residue

Often used with deionized or RO water to avoid streaks

Designed for lower cleaning frequency

Best for:

Coastal areas (salt deposits)

Industrial zones (oily residue, pollution)

Farms under birds migration routes

Regions with affordable water supply

Commercial rooftops where dirt is irregular and sticky

Key Advantages

Removes bonded contaminants

Requires fewer cleaning cycles

Beneficial after heavy storms or long periods without cleaning

Where IFBOT fits

The IFBOT M20 is a hybrid-capable robot that supports:

Wet cleaning with precise water control

Strong rollers that handle stubborn dirt

Remote control operation for safety

Designed for versatility across mixed environments

It’s especially valuable for C&I (Commercial & Industrial) sites where dirt varies by season.

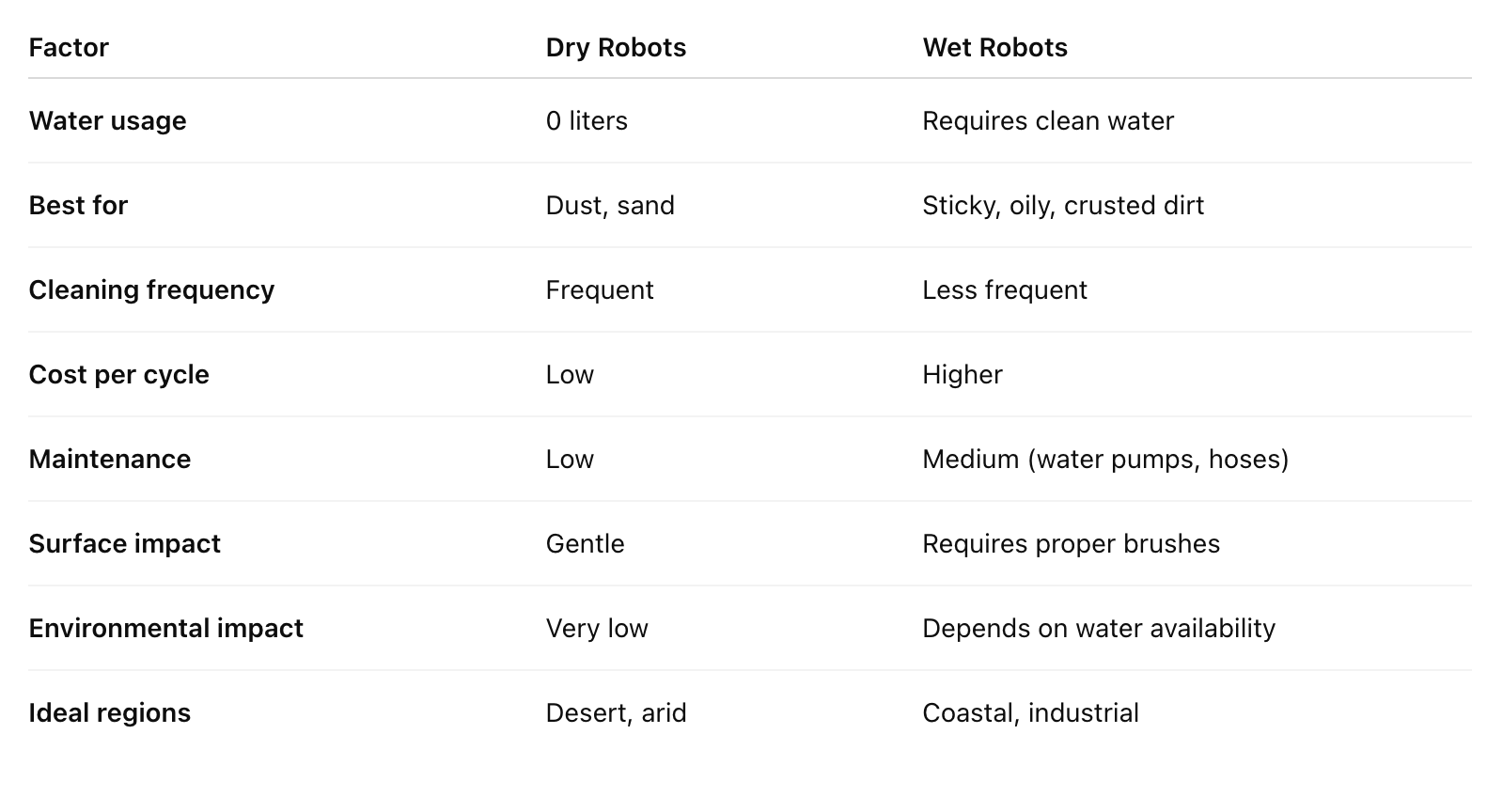

4. Dry vs Wet: A Side-by-Side Comparison

5. Which Robot Should You Choose?

Choose Dry Cleaning if:

Water is scarce

Dust accumulates daily

You manage large-scale solar plants

You prefer automated, daily cleaning

You want the lowest O&M cost

→ Best IFBOT option: X3

Choose Wet Cleaning if:

Panels get sticky stains or bird droppings

Water supply is available

You operate near the sea, factories, or airports

Your dirt problem is not just dust

→ Best IFBOT option: M20

In many cases, the correct answer is… both.

Many sites adopt:

Dry robots for regular cleaning, and

Wet robots for occasional deep cleaning

This balanced approach keeps panels producing at peak levels year-round with minimum cost.

6. How IFBOT Helps You Make the Right Choice

Choosing a solar panel cleaning solution shouldn’t feel like guesswork.

IFBOT supports you with:

Site condition assessment

Panel type evaluation

Cleaning frequency calculation

ROI estimation

Custom O&M strategy for your layout

Our robots (X3 and M20) are designed to perform in real-world conditions — from desert farms to dense industrial rooftops.

7. Final Takeaway

The difference between dry vs wet cleaning robots is not just about the cleaning method. It’s about:

How your site behaves

The dirt types you face

Water availability

Long-term maintenance

Efficiency and ROI

Environmental responsibilities

With the right robot, solar operators can recover power loss, reduce manual labor, protect panel surfaces, and save thousands of dollars annually.

IFBOT is here to support operators at every scale — with technology built for real problems, not theoretical ones.